Whangarei’s Top Choice AES Septic System Installations

AES (Advanced Enviro-SepticTM) is an on-site wastewater treatment system that is high quality, reliable, cost-competitive, environmentally sustainable, and requires no maintenance. It will save you money.

Now you can get a low-cost Combined Treatment and Disposal system for your septic tank that really works and helps you in the long run. It has parts that are built to last and a 20-year guarantee.

Free Instant Quote

** plus free bonus coupon **

Features & Benefits

Treatment of the Highest Quality

- When tested at NZ's OSET-NTP, the results of secondary treatment are 10 times better than the Aus/NZ Standard 1547 for Secondary Treatment.

- AES gets rid of a lot of pathogens without using disinfectants like UV filters or chlorine.

A silent and trustworthy system

- Not noisy because there are no pumps or alarms.

- Maintenance-free. No need for homeowners or plumbers to do regular checks. Just dump the septic tank when it's full.

- Power-free

Fit and Forget

- There are no pumps, control boards, aerators, or blowers that need to be replaced.

- There are no membranes or other parts to clean or replace.

- There's nothing to add!

- Just empty the septic tank's sludge every 3–7 years, as you would with any septic system.

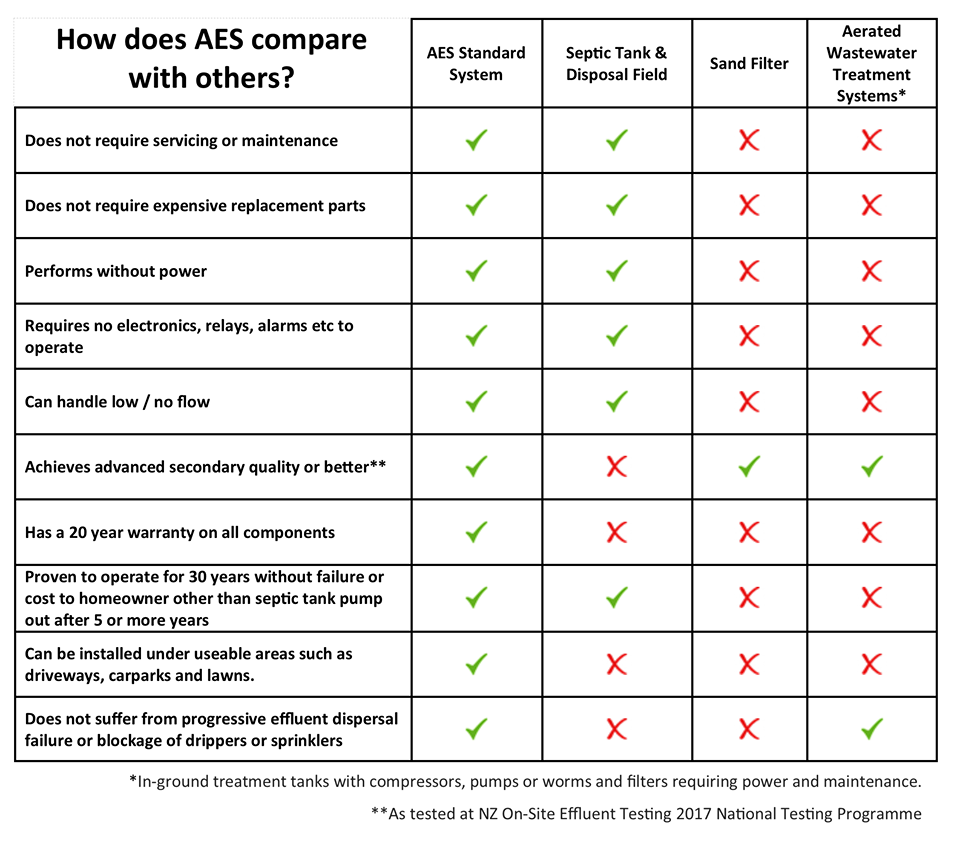

Why Choose AES Compared to other systems

Cost Savings

You can save more than $1,000 a year on electricity, maintenance contracts, filters, membranes, additives, or chemicals.

No expensive maintenance contracts every year. Most councils require that septic systems be checked at least once every six months. With the AES system, you don't have to do this.

No pump to replace at minimum $1,000.

Treatments that are natural and safe for the environment

No chemicals were added.

AES cleans up waste water by using natural biological processes.

The high quality of treatment and long life of the system keep the groundwater clean and reduce the chance of health problems.

Local Installation

AES uses local installers, septic tanks made in the same area, and system sand made in the same area.

Worm-free

No worm poop to throw away every six months.

When worms die, there's no need to get more.

Flexibility in design

AES installations can be made to fit a wide range of site conditions, and there are many ways to design them. AES systems can be used for greywater only, blackwater only, or for both greywater and blackwater. The treated waste water can be collected and used to water plants.

AES treatment beds can be straight, curved (up to 90 degrees), contoured, or shaped to fit around things.

Driveways can have AES put in under them.

AES can be put in a raised bed in places with a lot of groundwater.

Landscapers can use grasses or other plants with shallow roots to make treatment beds look nice. AES can be built into new projects or added to an existing septic tank to make it work like a secondary treatment system.

Proven to last long and have a good name around the world

AES parts are very long-lasting and can be used forever. An AES system will keep on working for you. When systems were dug up after 15–20 years, they were found to be working as they were meant to with clean, unclogged sand beds.

The parts have a 20-year warranty, which is longer than any other system.

Premier system worldwide. Since more than 25 years ago, AES systems have been installed in the United States, Europe, Australia, South Africa, and many other places, with long-lasting and reliable results.When tests are done carefully in North America, Europe, Australia, and New Zealand, the results are always of high quality.

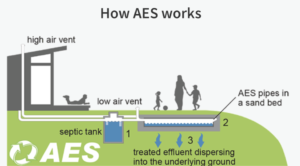

How On-site Septic Treatment Works

There are 3 levels of on-site septic treatment.

Primary Effluent Treatment

Raw effluent flows from a building or ablution block into a septic tank. Here, initial treatment is anaerobic (without air) as microbes in the effluent consume some of the suspended organic material. Inorganic material settles to the base of the tank and a scum layer floats on the surface sealing the majority of the effluent off from the air within the tank. Overflow from this tank is disposed of into a bed in the ground.

Secondary Treatment

Secondary effluent treatment is often a council requirement, and treats effluent to a higher level. Secondary treatment may be required when the disposal bed following primary treatment is on too small an area of land, is close to surface water or there is concern about groundwater contamination. Secondary treatment involves aerobic (in the presence of air) microbes resulting in the almost complete removal of dissolved and suspended organic matter from the effluent.

Dispersal to Ground

After these treatments, the effluent is usually required to be dispersed to a bed in the ground where soil bacteria and microbes in the soil consume whatever nutrients are left.

AES is a passive, on-site, advanced secondary wastewater treatment system that has been used in the United States for more than 25 years and has been installed in more than 500,000 places. Effluent is fed by gravity from a septic tank and treated by naturally occurring microbes in specially made, passively aerated pipes that are laid in a bed of sand. The rest of the highly treated effluent is spread out evenly in the sand bed through holes in the AES pipes, or it can be collected and used for irrigation instead. In the sand bed, there is more breakdown by microorganisms.

The key to the success of the AES system is passive ventilation through specially made AES pipes. These pipes create an environment where the microbes in the effluent can be broken down to a safe level. A normal AES system doesn't need pumps, filters, or any kind of maintenance. All that needs to be done is to pump out the septic tank every 5–7 years. AES is simple, uses natural processes, is good for the environment, and works very well.

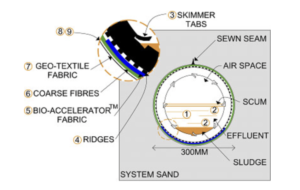

The most important part of the AES treatment process happens in oxygenated pipes with a 300mm diameter that are set in a sand bed in the ground. The septic tank's waste flows by gravity into the AES pipe system, where it meets a culture of naturally occurring microbes that break down solids and digest possible organic pollutants more quickly when they are exposed to air. Based on a "chimney" effect, air flows from a low-level inlet vent at one end of the AES pipe system to a high-level outlet vent at the other end.

The United States is where AES pipes were made. A mat of coarse, random fibers completely covers the pipes. This gives solids and bacteria more surface area for microbes to break down. Inside, skimmers remove grease and solids that are floating in the effluent.

The Bio-AcceleratorTM fabric at the bottom of the pipe makes it easier for microbes that can live on their own to form a biofilm that breaks down the organic matter. By making the pipe less permeable, this biofilm also makes sure that the effluent goes all the way through the pipe.

The United States is where AES pipes were made. A mat of coarse, random fibers completely covers the pipes. This gives solids and bacteria more surface area for microbes to break down. Inside, skimmers remove grease and solids that are floating in the effluent.

The Bio-AcceleratorTM fabric at the bottom of the pipe makes it easier for microbes that can live on their own to form a biofilm that breaks down the organic matter. By making the pipe less permeable, this biofilm also makes sure that the effluent goes all the way through the pipe.

How Does The AES System Work?

The AES system works by letting air flow through specially made AES pipes. This lets the microorganisms in the effluent break down to a level that is very safe. Simple, based on how nature works, good for the environment, scientifically proven, and very effective.

The most important part of the AES treatment process happens in oxygenated pipes with a 300mm diameter that are set in a sand bed in the ground. When waste water from the septic tank flows by gravity into the AES pipe system, it meets a culture of naturally occurring microorganisms that break down solids and digest potential organic pollutants more quickly when they are exposed to air.

The AES pipes are made of fabrics and fibers that give microorganisms a large surface area for breaking down solids and digesting possible organic pollutants. Aerobic bacteria can breathe better when there is a lot of air in the pipe system and the liquid levels change as the day goes on.

Venting

For secondary wastewater treatment to work, the environment needs to have oxygen in it. The pipes in an AES system do this with chimney effect venting, which is also known as differential venting. Air is pulled through a low-level inlet vent at the end of a line of AES pipes to a high outlet vent at least 3m above the low vent at the other end of the AES pipe system.

Most of the time, the AES bed ventilation system is different from the septic tank ventilation system.

The AES pipes were made in a special way.

The 300mm diameter pipes come in 3m sections that can be easily joined together to make long or wide pipe system beds.

A mat of coarse, random fibers completely covers the pipes. This gives solids and bacteria more surface area for microbes to break down. Inside, skimmers remove grease and solids that are floating in the effluent.

The effluent can flow all the way around the pipe without stopping because of the ridges. The Bio-AcceleratorTM fabric at the bottom of the pipe makes it easier for self-colonizing microorganisms to form a biofilm that breaks down the organic matter. By making the pipe less permeable, this biomat also makes sure that the effluent flows through the whole pipe. This is a cross-section of an AES (Advanced Enviro-SepticTM) pipe installed in a sand bed with an expanded section of the pipe's edge on top:

System Use

AES systems work best when one row is full to the top rather than when two or three rows are only half full. The last row will only get waste water when the home is at full capacity. So, when rows are connected in a row-by-row fashion, the first row is likely to get more waste water than the last row.

Even though this seems backwards compared to the usual way that primary treated effluent is spread out on the ground, there are benefits to the liquid rising and falling in each row of AES pipes. This is called the "lung effect," and as the liquid level rises and falls in the pipe system, it makes the best conditions for aerobic microbes.

After about 21 days, all of the pipes have been taken over by aerobic microorganisms, and a stable community has formed. A biomat is made, which lets the waste water flow through the pipe the whole way.

System Sand Bed

The rest of the highly treated liquid is drained into a bed of sand around the pipes and spread out evenly over the bed's base.

The size of the grains in this sand lets the waste water move slowly through the sand bed, where there is more space for microbes to break down the waste. So, the base of the AES bed gets an even amount of effluent that has been cleaned of BOD and TSS to less than 2 mg/100 ml, which is 10 times less than Secondary Standards.

Long Life

The life of an AES system is long. The AES system pipe does not fail in a way that gets worse over time because of how it is built. The pipes are very strong, and when systems are opened after 15 to 20 years, the sand beds are still clean.

This makes it easier for water to move through the AES system pipes and for oxygen to get to the microbiological processes going on in the sand.

AES parts are backed by a 20-year warranty. This is not offered by any other system.

Designed in the USA

David Presby, an engineer with a lifetime of experience in the wastewater industry, made the AES pipes and the AES wastewater treatment system.

Our Whangarei Grease Trap Cleaning Service Areas

- Cable Bay

- Coopers Beach

- Dargaville

- Haruru

- Hikurangi

- Kaikohe

- Kaitaia

- Kamo

- Kawakawa

- Kerikeri

- Mangawhai

- Mangonui

- Maungaturoto

- Moerewa

- Northland Septic Tank Cleaning

- One Tree Point

- Opua

- Paihia

- Ruakaka

- Ruawai

- Russell

- Taipa

- Waipu

(click to call on mobile)